In nature, the mother hen provides the optimal incubation environment for the embryonic development of her eggs. In commercial incubation, hatching eggs have precisely the same needs. They require the correct temperature, CO2/O2 concentration, humidity and turning angle. This article explains the importance of humidity in incubation and the biology behind it.

Nature: the strongest indicator for optimum incubation requirements

The attentiveness of the mother hen to her nest changes during the brooding period. In the first week, the mother hen sits firmly on the eggs. As the embryos get bigger, her attentiveness lessens and then it starts to increase again when the eggs are about to hatch. This way, the mother hen instinctively finetunes the temperature, oxygen and humidity levels for her eggs. Put differently, the mother hen’s activity in her natural environment is one of the strongest indicators for the optimum requirements of developing embryos and day-old chicks in commercial incubation.

Effects of humidity on embryonic development

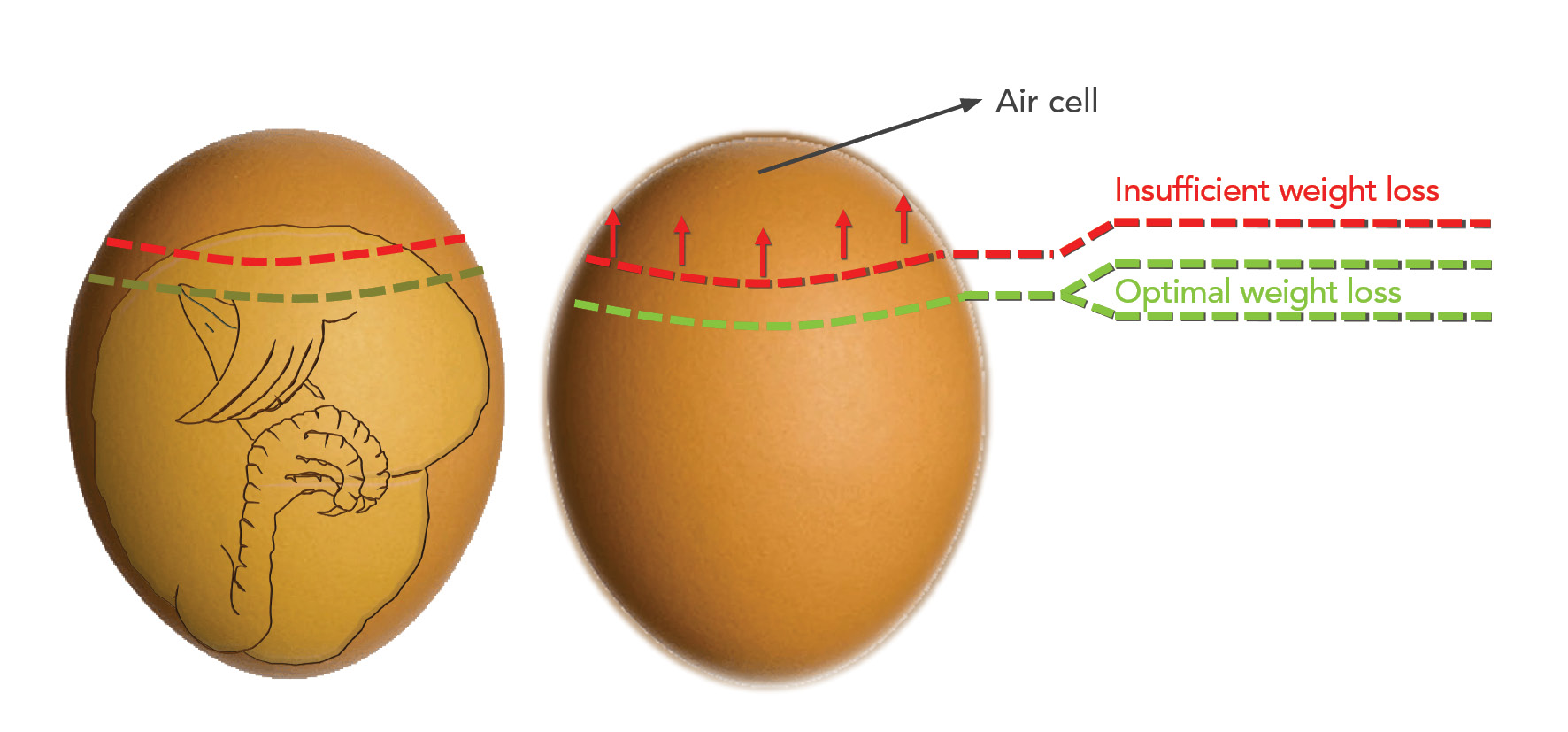

During incubation, all avian eggs lose water by diffusion through the pores in the eggshell. This water loss is needed to generate a healthy air cell size for the embryo to be able to inflate its lungs after internal pipping. Factors like the eggshell temperature and mainly the air humidity determine the rate at which the hatching eggs lose water and, as a result, lose weight. The higher the humidity level of the air surrounding the eggs, the lower the water loss (i.e. weight loss) rate.

The air cell can end up being too small if the eggs don’t lose enough water. Consequently, the embryo’s lungs cannot fully inflate and the newly born chick won’t be able to obtain enough oxygen for the hatching process, leading to an increased number of embryos pipping, but not hatching. On the other hand, too much water loss can cause embryo dehydration. Hence, regulating humidity during incubation is key to achieve optimal hatchability and chick quality.

Humidity and ventilation levels

Petersime’s incubation principle is based on the concept of non-linear weight loss, which imitates the humidity levels an embryo experiences when incubated – or brooded – naturally by the mother hen. The humidity level varies according to the different phases in the incubation process:

Phase 1: Development phase

During early incubation (days 1 to 9), the mother hen keeps all eggs warm at the same temperature by sitting firmly on the nest, limiting fluid and gaseous exchange. High humidity levels during this period are beneficial to the developing embryo. In a Petersime sealed, airtight setter, that same environment is created by limiting setter ventilation through CO2 setpoints, which allows a natural build-up of humidity. Air with a high relative humidity transfers heat more uniformly, ensuring a more uniform temperature inside the machine.

Phase 2: Growth phase

As the brooding progresses, the mother hen regularly leaves the nest, allowing more fresh air to surround the eggs (days 10 to 18). Increasing setter ventilation in this phase is important: A higher ventilation rate will remove humidity, which in turn allows the eggs to start losing water (weight) to finally result in a healthy air cell size and a good hatching position.

Phase 3: Hatching phase

During the hatching phase (days 19 to 21), the mother hen returns to the nest to sit on the eggs for the majority of time. She supports the embryos with positive stimuli during the entire hatching process. Inside the hatcher, the humidity increases naturally as the embryos start to hatch. Petersime’s hatcher technology uses two detection principles to monitor the hatch evolution and create the optimum hatching environment:

- Petersime’s Synchro-Hatch™ technology detects the so-called internal pipping (i.e. the moment the beak penetrates the inner shell membrane into the air cell). This biological signal is then used to initiate a sequence of modifications to the incubation environment to stimulate simultaneous hatching.

- In addition, the humidity sensor inside the Petersime hatcher monitors the actual humidity level and how far the hatching has progressed, with the humidity peak indicating that the great majority of chicks have hatched.

Influence of HVAC on incubation environment

Modern ventilation control systems inside setters and hatchers can automatically lower or raise the air-relative humidity levels: By monitoring the CO2 level inside the incubator, the system steers the level of ventilation through CO2 setpoints. Be aware that the hatchery’s HVAC (Heating, Ventilation and Air Conditioning) system also plays a key role . It ensures that the correct air volumes, conditioned both in terms of temperature and humidity, are delivered to the setter and hatcher room at all times. This allows the actual setters and hatchers to finetune the temperature and airflow, and provide optimum, uniform environmental conditions inside the machines.

In summary

Regulating humidity during incubation is key to achieve optimal hatchability and chick quality. Petersime is there for customers at every key stage of the hatchery’s life cycle. Please don’t hesitate to contact us if you would like help with a hatch result issue caused by humidity or other incubation-related questions.